Make encaustic cement tile to be a luxury brand

Encaustic cement tile - the tiles associated with childhood of the Vietnamese generation that were forgotten, but now has become "a luxury brand" exported to 45 countries. Mr. Dinh Hong Ky and his wife Mrs. Huong Vo Thi Lien called it as an "embroidery" tile.

(Hong Phuc)

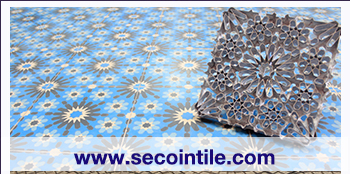

Each tile is an art

Encaustic cement tiles are handmade and non-burnt tiles. Therefore, although they are the same patterns, each tile has differentiation with "style" of artisans.

To be introduced to Vietnam by the Frenth since the 19th century, tiles gradually became the products widely used in Vietnam. The advantage of this tile is cool in summer and warm in winter. At the central-planning economy period, buildings, offices, hotels are tiled with this. In most buildings built by the French in Vietnam, the tiles had a presence as one hallmark characteristic.

However, by the 1990s, burnt and ceramic tiles began encroaching, encaustic cement tiles were almost "extinct". Quality of encaustic cement tiles were gradually decreased and they became cheaper products, primarily for sale to the poor people. Most tile makers had to quit and their life was unstable.

Meanwhile, in Europe, America or the Middle East, tiles are considered as luxury goods for the craftmanship (hand-made), and only rich people can afford to buy. In the Netherlands, France and Germany, due to high labor costs, the tile is priced at 100 euro account / square meter, while prices in Viet Nam were calculated only 2 euro / sqm. Mr. Ky repeatedly wondered why workers’ skills of making encaustic cement tiles in Vietnam is very well but Vietnam does not have any products to export to those markets? Dream of the new encaustic cement tiles – Vietnamese luxury brand was begun to form.

Mr. Ky went around Ho Chi Minh City and neighboring provinces to find the craftsmen who had ever made the tiles in Thanh Danh, Duc Tan, Doi Tan factories ... He asked those workers to find other workers and gather them, give them a good working conditions and promise to guarantee their lives.

Currently, Secoin encaustic cement tile factory has more than 200 workers who are over 60 years old with nearly 45 years of occupation, also are the first and long-life working tile workers ain Vietnam. Mrs. Lien Huong said: "Their income is much higher than previously, about 7-15 million VND / month not including 13th, 14th month of salary and other company policies . They are attached to the company ... "

However, things are not going so easy. The first Secoin factory was built in 2007 in Binh Duong with strategies aimed at exportation, but 90% of the waste. In the 2nd year, this percentage dropped to 60%. Mr. Ky required the workers to make 90 tiles/ day instead of 200 tiles/ day, but they must do it carefully and beautifully.

With skilled craftsmen, Mr. Ky and his wife went to learn about production technology in overseas, and at a fair in Germany, he found a chemical to enhance the quality of the Secoin encaustic cement tiles on a new vision. This "miracle water" mixed into painting color will create the tile to have beautiful, sharp drawing and especially not smudge patterns. Since then, Secoin tiles have a new face. Up to date, the failure rates of Secoin tile reduced to 1.6%. For the complex patterned tiles, workers make just 20 tiles each day. "It's like a painting, as works of art with high value creation, not just tiles ..." Mr. Ky said.

If ceramic tiles are such as hand-embroidered picture on the computer, the encaustic tile is purely a hand-embroidered picture. A ceramic tile factory with automatic production line can produce 5,000-10,000 square meters of tiles / day, the encaustic tile factory with the same scale production is only 200-300 square meters / day. He said this tile has a small market share but has its own position in the market and the huge potential. Rate of return is high. Currently this Secoin tile is priced about 600,000 VND/ square meter, the highest price in Vietnam and nearly double compared to other similar products in the domestic market but orders from overseas helped the production schedule of the factory nearly full throughout the next year.

The best value comes from hands

Secoin is not only famous for encaustic cement tile, Mr. Ky is also known as the king of outdoor tiles by the building companies, was a pioneer in the other non-burnt building materials.

He and his wife brought non-burnt tile technology from Italy to Vietnam, transferred to more than 20 manufacturing plants and named Terrazzo. It is also tiled along Hoan Kiem Lake. So far, the country had more than 150 large and small factories producing Terrazzo tiles.

Secoin company also provides equipment, technology transfer from abroad for 50 domestic non-burnt building material companies, is the company launched production technology for color roof tile with press in wet technoloy in Vietnam . "Non-burnt material is more durable and diversified. Making these products friendly environmental and having capability to regenerate are the criteria of our sustainable development. In the long term, we still focus on core business which is non-burnt tiles and tring every year with new products, "Mr. Ky said.

Be experienced the the challenges, as many investors had asked to buy the company (but Mr. Ky does not sell), or friends recommended to lauch shares to become a billionaire in one night. For a while, he and his wife opened the abraive stone factory and losses, to move through the tile production. Or investing in particle board wood were failed and had to sell it ... The way to successful business stories of Secoin couples boss today have actually gone through many up and down situations .

The lesson Mr. Ky learned is to focus on core business. "It's hard, if we compete with the world by plane, car or computer. But when we have built our own values, we will have a place in the world. If I release shares, stocks or invest in rambling real estate, I did not have Secoin today”, Mr. Ky shared.

Today, Secoin brings pride to Mr. Ky’s family. Maybe, every Secoin worker generates less revenue but with Mr. Ky, the most precious value is generated from products made by hands, not only buy to resell for profit. "I do not take to reach too big goals. I just wanted to do good for the family and my workers. Do not exploit them, do not owe their salary was already hard then...", Mr. Ky said.

Percentage of ownership of Mr. Ky’s his family is about 70% in Secoin. With the successful stories of the family company in the world, Mrs. Lien Huong said they will maintain the model of the family company in the long run. According to Mrs. Huong, without thinking through the term, family-owned business model has certain stability. And in the current economic context, this is the right business model and sustainability.

Translation from The Saigon Times published on 25th December 2014

Written : admin

.png)